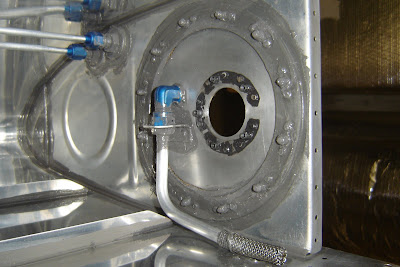

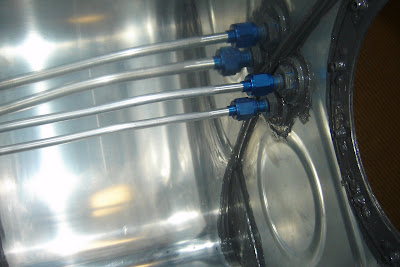

After ordering the 5 dollar leak kit from Vans, I commenced with the test. First you cap off the fuel pick up, then connect balloons to the vents(I rigged up some tubing and zip ties to help get a tight fit around the

balloons). Next, I placed a latex glove around the fuel cap and put it in place. Then I inserted the fitting, supplied by vans, into the quick drain and slowly pumped air into the tank until the balloons started to fill. I then disconnected the hand pump and started spraying a soap and water mixture over the tank. Finally, I did a careful inspection over the entire tank.

I am VERY HAPPY to report that I have found NO LEAKS! The

balloons have held air through the night and continue to do so......

Update- After a week, the ballons were still inflated to the same size so I disconnected everything and moved on.

Tip: Place a latex glove over the fuel cap before testing. I've heard this helps provide a good tight seal. It worked for me..... (Vans recommends putting tape over the cap)