The Wing Install is Complete! Yes, It was a real pain, but doable with the right tools. It took us a total of 5 hrs to complete. *Special Thanks to Chris Fendley, Udo Reif, and Jeff Johnson.

It's finally an airplane at this point, Sweet!

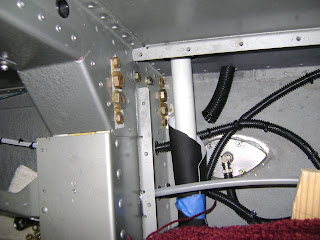

Right Side, Aft Main Spar. Here, All 10 bolts, per side, have been installed. I needed 3 washers for each bolt. One under the head, and two under the nut. You may also notice the electrical conduit that I ran into the fuselage. The black wrap was used to help prevent chaffing of the aileron push tubes. It was removed just after this pic was taken.

It's finally an airplane at this point, Sweet!

Right Side, Aft Main Spar. Here, All 10 bolts, per side, have been installed. I needed 3 washers for each bolt. One under the head, and two under the nut. You may also notice the electrical conduit that I ran into the fuselage. The black wrap was used to help prevent chaffing of the aileron push tubes. It was removed just after this pic was taken.

I was able to torque the Right side from the nuts and the Left side from the heads.

*Note - NAS bolts have different torq settings than AN bolts.

NAS 1304 80-100 inch/lbs NAS 1307 520-630 inch/lbs AN4 Bolts 50-70 inch/lbs

Wing Bolt Notes

1- Prepare early by doing research on the VAF site, gather all the required tools, and look over plans pg. 80

2- Make sure all of the prep work is Done. (Aileron push tubes installed, fuel level sender wire hole drilled, 1/4 gap cut in front brackets(use an Air saw), rear air vent hose ready for install,etc

3-Freeze the Bolts, Make drift/alignment Pins from hardware store bolts

4- Take Your Time, Have at least 3 helpers

5- Lube the bolt shanks, drifting pins, and holes prior to install.

6-Acquire an Air Ratchet, Rivet Gun (with flush set), small Ball Peen Hammer, Box Wrenches/Sockets/Crows Feet(5/8,11/16,7/16 etc.), Various Extensions, Breaker bar, Mirror, Magnet, Grease, Rubber Gloves, Head Lamp, Drop Light,etc.

1 comment:

Wow! Congratulations. I am very excited for you!

Post a Comment